X Bar Range Chart

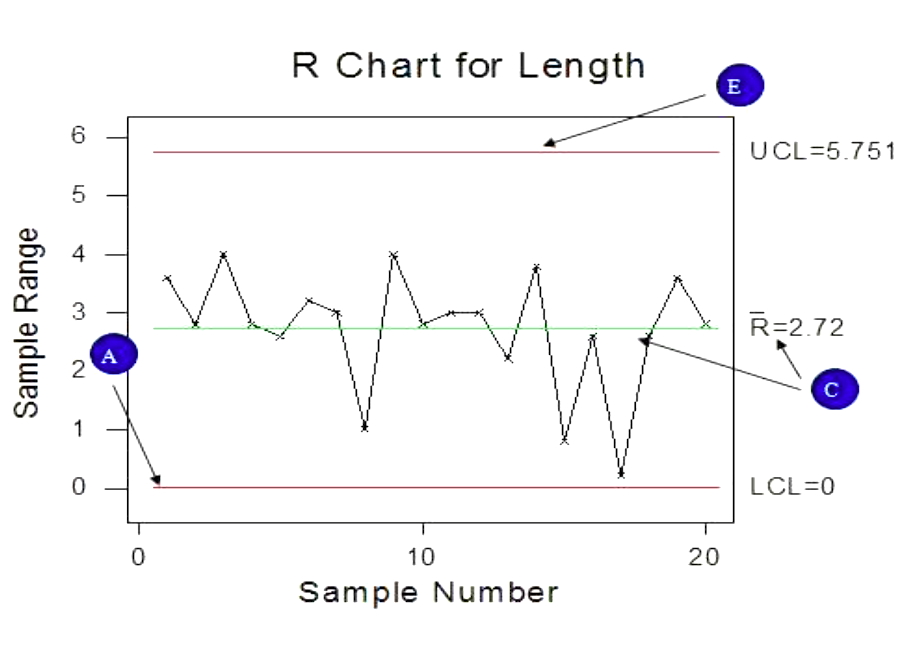

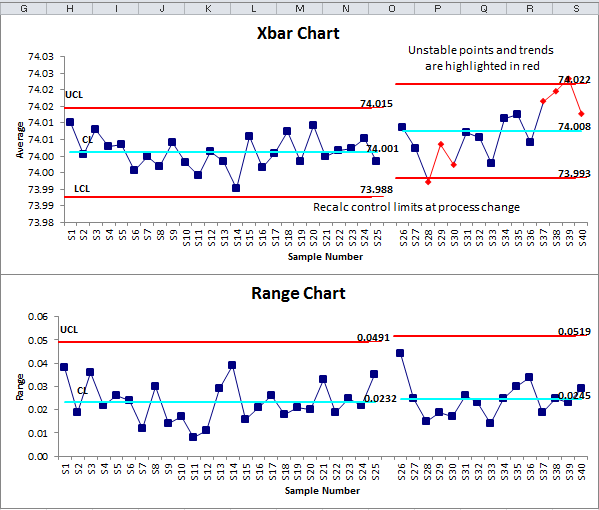

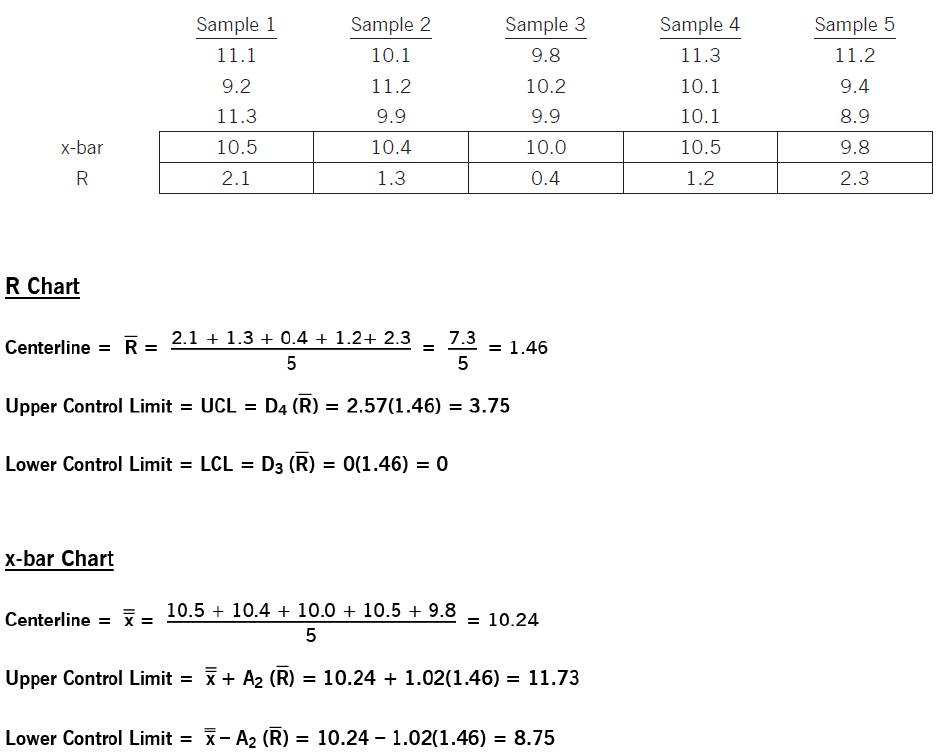

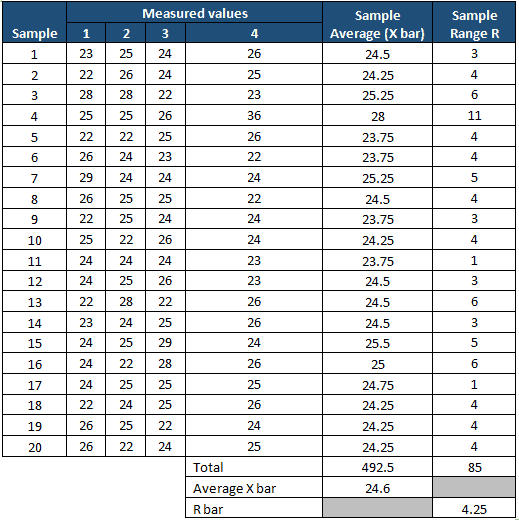

X Bar Range Chart - Click on the “insert” tab in the excel ribbon, then click on the “column” button and select “clustered column” from the dropdown menu. If the points are out of control in the r chart, then stop the process. If the r chart’s values are out of control, the x bar chart control limits are inaccurate. Below are the x bar r chart formula that used in the qi macros for both range & avg (xbar) charts. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. N28°25.76' / w81°18.54' located 06 miles se of orlando, florida on 11605 acres of land. Web enroute charts at skyvector.com location information for kmco coordinates: Identify the special cause and address the issue. This should include the category labels in the rows and the corresponding data values in the columns. Select the method or formula of your choice. Web the xbarr chart can help you evaluate the cycle time for almost any process: In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. If the points are out of control in the r chart, then stop the process. Making a widget, answering a customer call, seating a customer, delivering a pizza, or servicing an appliance. Each plotted point, , represents the mean of the observations for subgroup,. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Quality engineers at a manufacturing plant monitor part lengths. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Web enroute charts at skyvector.com location information for korl coordinates: Identify the special cause and address the issue. Here is some further information about the charts. N28°32.73' / w81°19.98' located 03 miles e of orlando, florida on 969 acres of land. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart,. Web enroute charts at skyvector.com location information for kmco coordinates: They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Quality engineers at a manufacturing plant monitor part lengths. Web the. If the r chart’s values are out of control, the x bar chart control limits are inaccurate. Web the x bar chart controls limits that are derived from the r bar (average range) values. Each plotted point, , represents the mean of the observations for subgroup,. Below are the x bar r chart formula that used in the qi macros. This chart is especially useful when you do this many times a day. Identify the special cause and address the issue. N28°32.73' / w81°19.98' located 03 miles e of orlando, florida on 969 acres of land. Quality engineers at a manufacturing plant monitor part lengths. Web the x bar chart controls limits that are derived from the r bar (average. Web bar controls of florida offers a wide variety of drink products and dispensing equipment to satisfy all of your beverage needs. This should include the category labels in the rows and the corresponding data values in the columns. N28°32.73' / w81°19.98' located 03 miles e of orlando, florida on 969 acres of land. In statistical process control (spc), the. Making a widget, answering a customer call, seating a customer, delivering a pizza, or servicing an appliance. Identify the special cause and address the issue. Web bar controls of florida offers a wide variety of drink products and dispensing equipment to satisfy all of your beverage needs. N28°32.73' / w81°19.98' located 03 miles e of orlando, florida on 969 acres. Web enroute charts at skyvector.com location information for korl coordinates: Web the xbarr chart can help you evaluate the cycle time for almost any process: Web enroute charts at skyvector.com location information for kmco coordinates: This chart is especially useful when you do this many times a day. If the points are out of control in the r chart, then. This chart is especially useful when you do this many times a day. Select the method or formula of your choice. N28°25.76' / w81°18.54' located 06 miles se of orlando, florida on 11605 acres of land. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Web x bar r chart formulas. Web bar controls of florida offers a wide variety of drink products and dispensing equipment to satisfy all of your beverage needs. Click on the “insert” tab in the excel ribbon, then click. Web bar controls of florida offers a wide variety of drink products and dispensing equipment to satisfy all of your beverage needs. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Each plotted point, , represents the mean of the observations for subgroup,. Select the method or formula of your choice.. Web enroute charts at skyvector.com location information for kmco coordinates: N28°25.76' / w81°18.54' located 06 miles se of orlando, florida on 11605 acres of land. N28°32.73' / w81°19.98' located 03 miles e of orlando, florida on 969 acres of land. Making a widget, answering a customer call, seating a customer, delivering a pizza, or servicing an appliance. This chart is especially useful when you do this many times a day. Quality engineers at a manufacturing plant monitor part lengths. Web the x bar chart controls limits that are derived from the r bar (average range) values. Below are the x bar r chart formula that used in the qi macros for both range & avg (xbar) charts. If the points are out of control in the r chart, then stop the process. Web the xbarr chart can help you evaluate the cycle time for almost any process: Web enroute charts at skyvector.com location information for korl coordinates: Each plotted point, , represents the mean of the observations for subgroup,. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Select the method or formula of your choice. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Here is some further information about the charts.Control Charts Enhancing Your Business Performance

X Bar R Chart Excel Average and Range Chart

Xbar and range chart (What is it? When is it used?) Data analysis

SPC XBAR and Range Chart CodeProject

How To Create an XBar R Chart Six Sigma Daily

Xbar (Mean) chart and R (Range) chart. John S. Oakland (2003

Xbar (Mean) and R (Range) chart. John S. Oakland (2003). Download

X Bar R Control Charts

A2 Chart For X Bar

Control Chart X Bar

Web X Bar R Chart Formulas.

In Statistical Process Control (Spc), The And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed Variables Simultaneously, When Samples Are Collected At Regular Intervals From A Business Or Industrial Process.

This Should Include The Category Labels In The Rows And The Corresponding Data Values In The Columns.

Analyzing The Pattern Of Variance Depicted By A Quality Control Chart Can Help Determine If Defects Are Occurring Randomly Or Systematically.

Related Post: