Wheel Stud Torque Chart

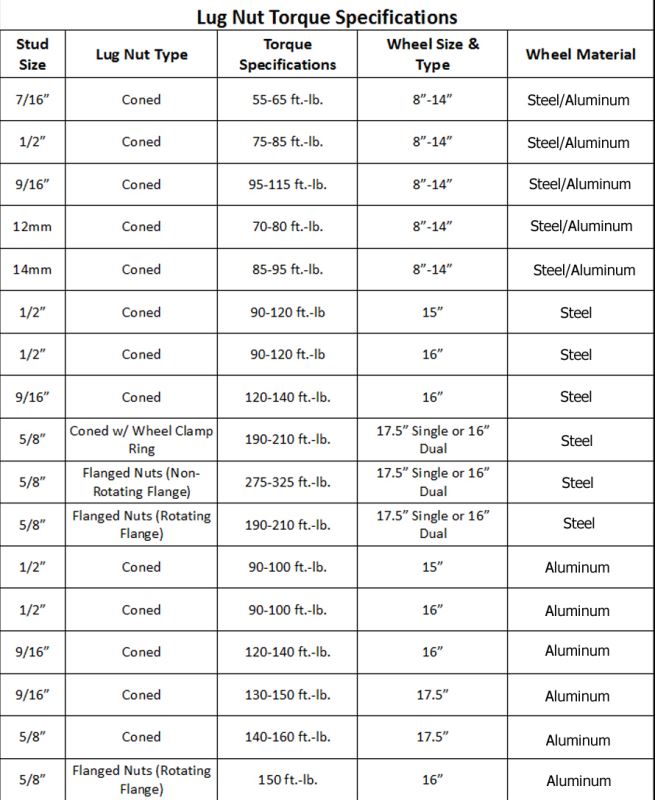

Wheel Stud Torque Chart - Web proper torque, which stretches the bolt, causes the threads of the stud/bolt to tightly mate and secure to the matching nut or threaded hole (within the axle or wheel hub) without working themselves loose. Next, tighten to the recommended torque following the proper sequence shown below for your wheel type. The chart will have information such as the size of the lug nut, its thread pitch, and the amount of torque needed to properly secure it. Web lug nut torque specs are the recommended tightening specifications for lug nuts on a vehicle. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. Web wheel nut torque specifications (shown in ft. Properly torquing lug nuts is essential in order to maintain safety while driving. Web wheel torque sequence chart for wheel nut installation. For the most part, you’re looking at numbers between 80 and 120 foot pounds of torque. (r) remove debris from mounting surfaces, (i) inspect components for damage or excessive wear, (s) snug the lugs in a star pattern, and (t) torque to manufacturer specifications. (r) remove debris from mounting surfaces, (i) inspect components for damage or excessive wear, (s) snug the lugs in a star pattern, and (t) torque to manufacturer specifications. Next, tighten to the recommended torque following the proper sequence shown below for your wheel type. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. The chart gives you the recommended torque specs for many common vehicles, including those made. Web these charts have the torque specification for use with original equipment wheels; The formula for calculating the torque required to tighten wheel bolts or lug nuts is as follows: Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. There isn’t a specific answer for this, and it depends on multiple factors, including the size of the bolts, the type of wheel, and the manufacturer’s specifications. Web if you are planning on installing a wheel on your vehicle, it is important to be aware of the manufacturer recommended torque settings. For the most part, you’re looking at numbers between 80 and 120 foot pounds of torque. Torque (t) = wheel stud diameter (d) x friction coefficient (f) x lever arm (l) where: Web proper torque, which stretches the bolt, causes the threads of the stud/bolt to tightly mate and secure to the matching nut or threaded hole (within the axle or wheel hub) without working themselves loose. Web if you are planning on installing a wheel. The chart gives you the recommended torque specs for many common vehicles, including those made. Durable, folded, coated chart for longer wear; Web to make sure you’ve got the right torque for your lug nuts, we’ve created a free and printable lug nut torque chart pdf. It serves as a guide to making sure you apply the right amount of. Web simply put, wheel torque represents a rotational force that is applied when you tighten a lug nut or bolt. There isn’t a specific answer for this, and it depends on multiple factors, including the size of the bolts, the type of wheel, and the manufacturer’s specifications. Properly torquing lug nuts is essential in order to maintain safety while driving.. Web wheel torque specs vary based on stud diameter, wheel diameter and wheel material. We recommend using the rist method of lug installation: Web proper torque, which stretches the bolt, causes the threads of the stud/bolt to tightly mate and secure to the matching nut or threaded hole (within the axle or wheel hub) without working themselves loose. It serves. Next, tighten to the recommended torque following the proper sequence shown below for your wheel type. Web wheel nut torque specifications (shown in ft. We recommend using the rist method of lug installation: Learn more about proper lug nut torque specifications for your vehicle. Other nut designs have different torque requirements. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. Position one of the hub’s pilot pads at the twelve o’clock position. For the most part, you’re looking at numbers between 80 and 120 foot pounds of torque. Web wheel torque specs vary based on stud diameter, wheel diameter and wheel material. Web once. For the most part, you’re looking at numbers between 80 and 120 foot pounds of torque. Torque (t) = wheel stud diameter (d) x friction coefficient (f) x lever arm (l) where: There isn’t a specific answer for this, and it depends on multiple factors, including the size of the bolts, the type of wheel, and the manufacturer’s specifications. Web. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. Lbs.) make/model years torque acura all models except: The linked chart shows you commonly recommended torque specs for a range of studs and wheels. Web what is the torque spec for wheel bolts? Web lug. Using the proper torque helps ensure that the wheel assembly is securely installed. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. Position one of the hub’s pilot pads at the twelve o’clock position. Web • the correct nut torque sequence for the wheel must be used, to correctly and centrally locate the. (r) remove debris from mounting surfaces, (i) inspect components for damage or excessive wear, (s) snug the lugs in a star pattern, and (t) torque to manufacturer specifications. Web wheel torque specs vary based on stud diameter, wheel diameter and wheel material. Web what is the torque spec for wheel bolts? Web torque the lug nuts in two steps, starting. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. There isn’t a specific answer for this, and it depends on multiple factors, including the size of the bolts, the type of wheel, and the manufacturer’s specifications. Web simply put, wheel torque represents a rotational force that is applied when you tighten a lug nut or bolt. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. Durable, folded, coated chart for longer wear; Torque (t) = wheel stud diameter (d) x friction coefficient (f) x lever arm (l) where: The chart will have information such as the size of the lug nut, its thread pitch, and the amount of torque needed to properly secure it. (r) remove debris from mounting surfaces, (i) inspect components for damage or excessive wear, (s) snug the lugs in a star pattern, and (t) torque to manufacturer specifications. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. The chart gives you the recommended torque specs for many common vehicles, including those made. Web these charts have the torque specification for use with original equipment wheels; Below you will find wheel lug nut torque specs for most us makes and models with data from dorman products. Web • the correct nut torque sequence for the wheel must be used, to correctly and centrally locate the wheel on the hub of the trailer or caravan • it is imperative that the final wheel nut torque be achieved manually, using a properly calibrated, high For the most part, you’re looking at numbers between 80 and 120 foot pounds of torque. Other nut designs have different torque requirements. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts.4DIYers Wheel Stud Torque Specifications

4DIYers Wheel Stud Torque Specifications

4DIYers Wheel Stud Torque Specifications

Lug Nut Torque Specs Ford

Wheel Lug Nut Torque for 1/2Inch Stud and 12Inch

Vw Wheel Torque Chart

Honda Lug Nut Torque Spec

4DIYers Wheel Stud Torque Specifications

Printable Automotive Wheel Torque Chart

4DIYers Wheel Stud Torque Specifications

Web Wheel Torque Sequence Chart For Wheel Nut Installation.

Web Wheel Nut Torque Specifications (Shown In Ft.

Lbs.) Make/Model Years Torque Acura All Models Except:

The Linked Chart Shows You Commonly Recommended Torque Specs For A Range Of Studs And Wheels.

Related Post: