Electrical Lug Torque Specs Chart

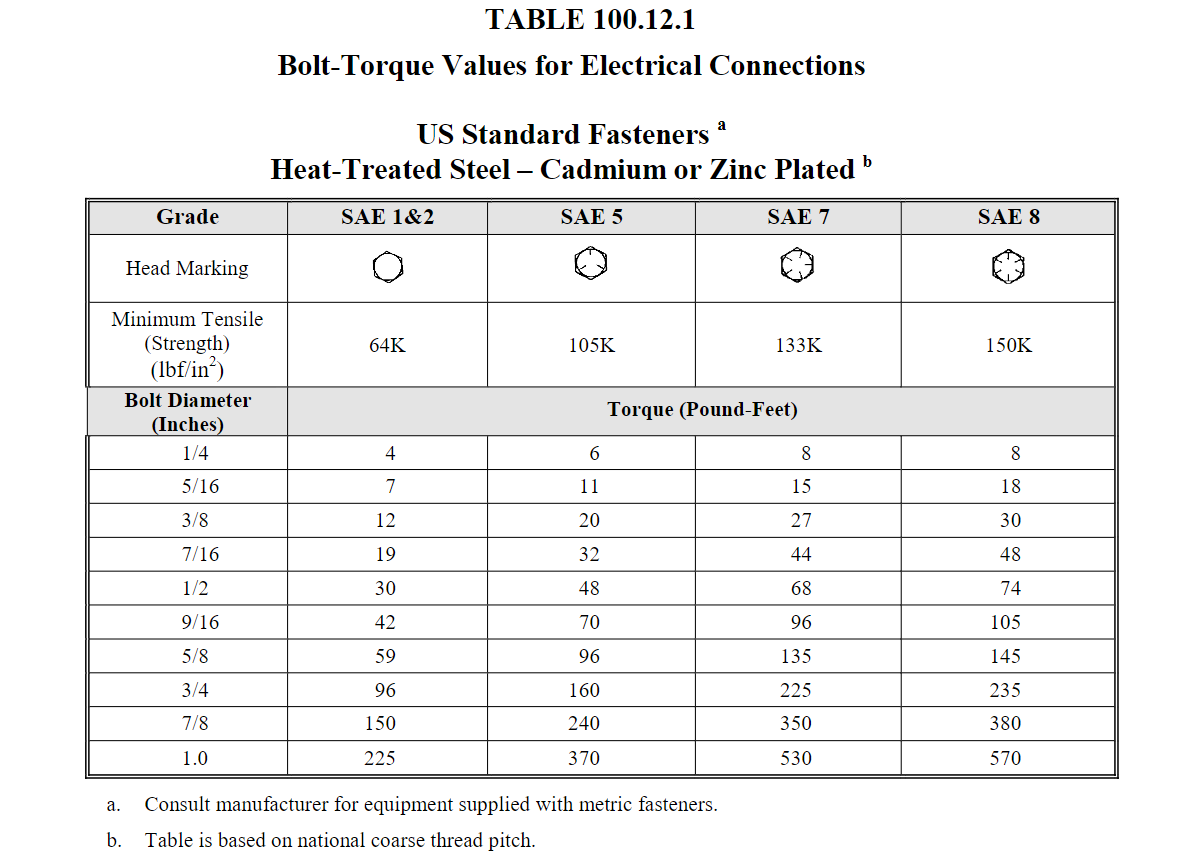

Electrical Lug Torque Specs Chart - Lug tightening torque for wire binding screw for both the al and cu lugs is 375 in lbs. Blue highlighted items are industry standard and most frequently ordered. • what data do we have in the industry and what do the connector standards † conductors must be of equal size. Web torque specs are often listed on the manufacturer’s literature, on the actual lug or terminal, or even on the front or side of the circuit breaker. Tightening torque for the lug retaining nut is 75 in lbs. If the threads of the lug are dry or not lubricated it will reach the recommended torque setpoint sooner than one that is lubricated. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Tables 3 has specs for allen lugs. Web customers need to know torque spec for wire binding screw and lug retaining nut. Web the torque screwdriver can be used to tighten and loosen screw connections, but its primary function is to tighten torque connections to a specific value. Web what is the torque specs of these lugs? Web torque specs are often listed on the manufacturer’s literature, on the actual lug or terminal, or even on the front or side of the circuit breaker. Web connection torque values for main lug compartments and connection torque values for main and branch feeders provide main disconnect and branch feeder torque values, which apply to both aluminum and copper conductors. Web learn about the torque specifications for eaton wiring devices and connectors, including the recommended torque values and installation instructions for various products. Bolts and nuts are new, standard finish, uncoated and not lubricated*. Here are a few examples: Tightening torque values for ilsco sockethead screw connectors. The load will be 90% of the bolt yield strength. These lugs have torque marks and a '41' wrote on them. If the threads of the lug are dry or not lubricated it will reach the recommended torque setpoint sooner than one that is lubricated. It comes in a standard nema 1 enclosure or optional nema 3r, 4, or 12 enclosures. Tightening torque for the lug retaining nut is 75 in lbs. Tightening torque in inch pounds. Web • what is. The load will be 90% of the bolt yield strength. These lugs have torque marks and a '41' wrote on them. Internal socket size across flats inches. Web learn about the torque specifications for eaton wiring devices and connectors, including the recommended torque values and installation instructions for various products. Web ses 75% of the yield strength. Web in preparing this guide to torque values, the following basic assumptions have been made: Tightening torque values for ilsco sockethead screw connectors. Is that for the mounting bolts, the conductor lug screws, or both? It comes in a standard nema 1 enclosure or optional nema 3r, 4, or 12 enclosures. Web learn about the torque specifications for eaton wiring. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Web • what is torque at the engineering level and how does that translate to electrical connections? Is that for the mounting bolts, the conductor lug screws, or both? The coefficient of friction (μ) is 0.14. It explains that. Tightening torque values for ilsco sockethead screw connectors. Web in preparing this guide to torque values, the following basic assumptions have been made: Web these lugs are attached to the main breaker with a flathead screw, and that doesn't seem quite strong enough to hold the lug while torquing. Web this document provides information about torque values for electrical lugs. Web ses 75% of the yield strength. Web customers need to know torque spec for wire binding screw and lug retaining nut. See the attached instruction below referencing page 53. The coefficient of friction (μ) is 0.14. It comes in a standard nema 1 enclosure or optional nema 3r, 4, or 12 enclosures. The load will be 90% of the bolt yield strength. Web proper torque is a figure recommended by the manufacturer of the terminal. Does it depend on the wire size and material or the torque depends on the bolt size? Web torque specs are often listed on the manufacturer’s literature, on the actual lug or terminal, or even on the. The rated clockwise tightening torque number on a mechanical lug is an exact torque, not a minimum or a maximum. Bolts and nuts are new, standard finish, uncoated and not lubricated*. † conductors must be of equal size. Does it depend on the wire size and material or the torque depends on the bolt size? I found on the manufacturer. But then consider a copper/aluminum lug. What are the electrical connection torque specifications for a qed switchboard (swbd)? Web this document provides information about torque values for electrical lugs and links to download related documents. • what data do we have in the industry and what do the connector standards Tightening torque in inch pounds. Web • what is torque at the engineering level and how does that translate to electrical connections? Web this document provides information about torque values for electrical lugs and links to download related documents. Web connection torque values for main lug compartments and connection torque values for main and branch feeders provide main disconnect and branch feeder torque values, which. Web nec 2017, 2020, 2023, annex i all have references with torque specs. Web learn about the torque specifications for eaton wiring devices and connectors, including the recommended torque values and installation instructions for various products. Web the eaton elevator control es switch meets prevailing ansi/asme, nec® and nfpa 72 requirements in a ul 98 listed (enclosed switch) and ul 50 listed (enclosure) unit. Bolts and nuts are new, standard finish, uncoated and not lubricated*. Web these lugs are attached to the main breaker with a flathead screw, and that doesn't seem quite strong enough to hold the lug while torquing. Tightening torque in inch pounds. Is that for the mounting bolts, the conductor lug screws, or both? Tightening torque in inch pounds. It explains that the online library contains portable document format (pdf) files with information on torque specifications for electrical connections. Web customers need to know torque spec for wire binding screw and lug retaining nut. Tightening torque for the lug retaining nut is 75 in lbs. These lugs have torque marks and a '41' wrote on them. Here are a few examples: Web connection torque values for main lug compartments and connection torque values for main and branch feeders provide main disconnect and branch feeder torque values, which apply to both aluminum and copper conductors. Blue highlighted items are industry standard and most frequently ordered. The load will be 90% of the bolt yield strength.Electrical Wire Lug Torque Chart

Nec Electrical Lug Torque Specs Chart Printable Templates Free

Electrical Lug Torque Specs Chart Square D

Wire Lug Torque Specs Chart

Electrical Lug Torque Chart

Electrical Lug Torque Specs Chart Siemens

Nec Electrical Lug Torque Specs Chart

Nec Electrical Lug Torque Specs Chart

Electrical Lug Torque Chart

Electrical Lug Torque Specs Chart Eaton

Web • What Is Torque At The Engineering Level And How Does That Translate To Electrical Connections?

Web Torque Specs Are Often Listed On The Manufacturer’s Literature, On The Actual Lug Or Terminal, Or Even On The Front Or Side Of The Circuit Breaker.

Web The Professional Electrical Apparatus Recycler's League ( Pearl ) Has Generic Torque Specifications In Table 1 Of Their Reconditioning Standard.

It Comes In A Standard Nema 1 Enclosure Or Optional Nema 3R, 4, Or 12 Enclosures.

Related Post: