Chain Grade Chart

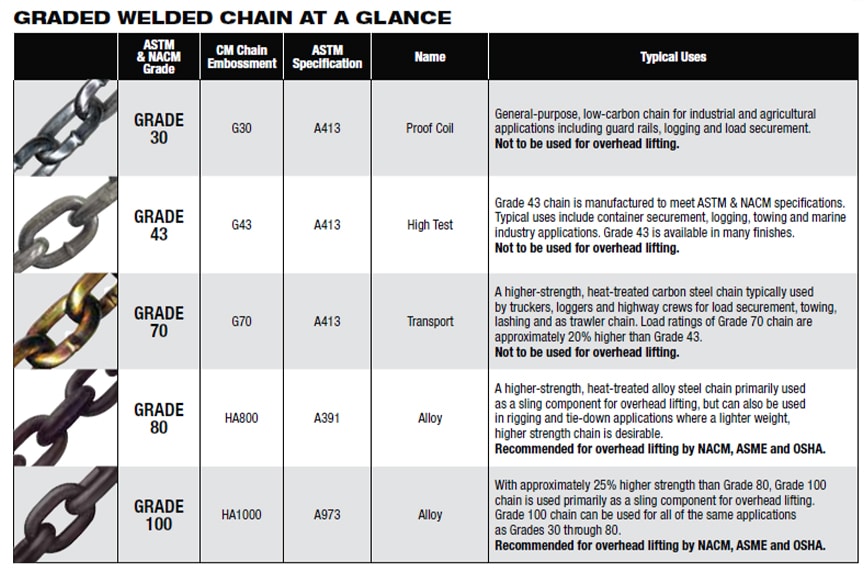

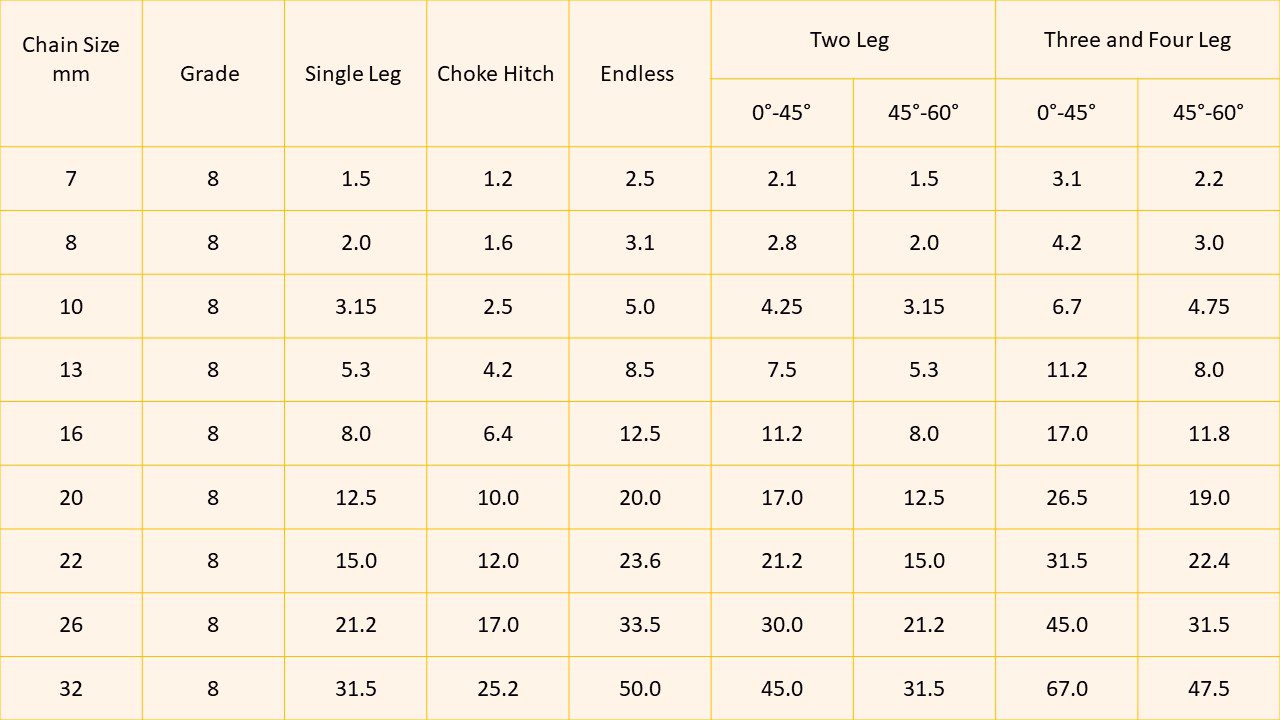

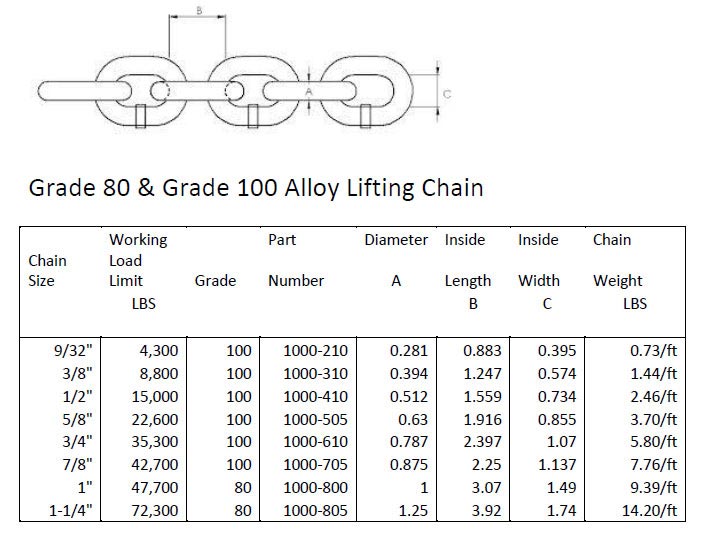

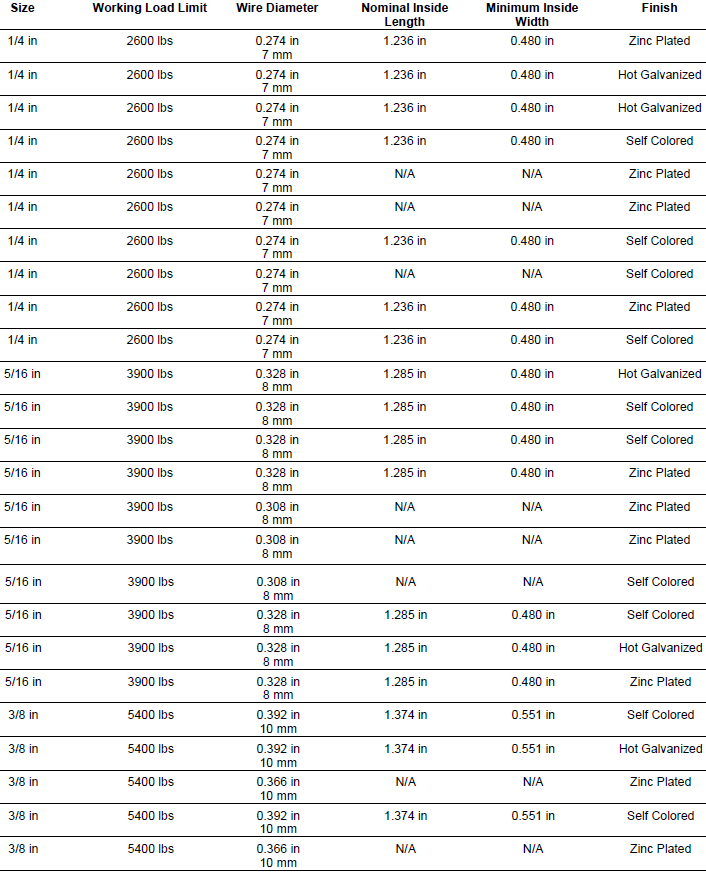

Chain Grade Chart - Web chains come in various grades, each denoting specific characteristics and applications. Web complete flatbedder’s guide on cargo chain grades, grade types and chain strength with chart. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade 80, 100, and 120—is recommended for use in sling assemblies and overhead lifting applications. Grades help determine what sort of applications are appropriate for a given chain. Learn how to identify grades and marking of transport chains. Web there are five grades of chain: G30, g43, g70, g80, and g100. Web this guide will delve into the various chain grades used in the rigging industry, their common applications, differences, potential problems, and common misuse scenarios. Web in the intricate world of industrial chains, understanding the grading system is paramount. Common grades include grade 30, grade 43, grade 70, grade 80, and grade 100, each tailored for distinct use cases. Alloy chain grade 80 or grade 100 should be used for overhead lifting. Web chains come in various grades, each denoting specific characteristics and applications. Chain grades are determined by calculating newtons per square millimeter, using the formula “n/mm 2 ”. Web this guide will delve into the various chain grades used in the rigging industry, their common applications, differences, potential problems, and common misuse scenarios. Web there are five grades of chain: Web in this article, we unravel the intricacies of identifying chain grade, shedding light on the key factors, markings, and insights that empower industries to distinguish between different chain grades accurately. G30, g43, g70, g80, and g100. This article embarks on a journey through the ratings of chain grades, deciphering the significance behind the numbers and letters that define strength, durability, and performance. Astm states that alloy chain shall be able to elongate a minimum of 20% before fracture (7.3.5). Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade 80, 100, and 120—is recommended for use in sling assemblies and overhead lifting applications. Chain grades are. Web this guide will delve into the various chain grades used in the rigging industry, their common applications, differences, potential problems, and common misuse scenarios. Web in the intricate world of industrial chains, understanding the grading system is paramount. Web which chain grade should be used for which type of application? Web the biggest difference between grades of chain is. Web chains come in various grades, each denoting specific characteristics and applications. Learn how to identify grades and marking of transport chains. Web there are five grades of chain: Web in this article, we unravel the intricacies of identifying chain grade, shedding light on the key factors, markings, and insights that empower industries to distinguish between different chain grades accurately.. Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Web which chain grade should be used for which type of application? Web this guide will delve into the various chain grades used in the rigging industry, their common applications, differences, potential problems, and common misuse scenarios. Grades wise chain usage and safety. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade 80, 100, and 120—is recommended for use in sling assemblies and overhead lifting applications. Grades help determine what sort of applications are appropriate for a given chain. Chain grades are determined by calculating newtons. Web in the intricate world of industrial chains, understanding the grading system is paramount. Web there are five grades of chain: G30, g43, g70, g80, and g100. Web chains come in various grades, each denoting specific characteristics and applications. Web chain grades are a standard method for showing the ultimate breaking strength (tensile strength) of a chain. Grades help determine what sort of applications are appropriate for a given chain. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade 80, 100, and 120—is recommended for use in sling assemblies and overhead lifting applications. Web chains come in various grades, each. Web which chain grade should be used for which type of application? Web there are five grades of chain: Alloy chain grade 80 or grade 100 should be used for overhead lifting. Grades help determine what sort of applications are appropriate for a given chain. Astm states that alloy chain shall be able to elongate a minimum of 20% before. Web which chain grade should be used for which type of application? Learn how to identify grades and marking of transport chains. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade 80, 100, and 120—is recommended for use in sling assemblies and overhead. Web in the intricate world of industrial chains, understanding the grading system is paramount. Common grades include grade 30, grade 43, grade 70, grade 80, and grade 100, each tailored for distinct use cases. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade. G30, g43, g70, g80, and g100. Web in the intricate world of industrial chains, understanding the grading system is paramount. Chain grades are determined by calculating newtons per square millimeter, using the formula “n/mm 2 ”. Grades help determine what sort of applications are appropriate for a given chain. Web in this article, we unravel the intricacies of identifying chain grade, shedding light on the key factors, markings, and insights that empower industries to distinguish between different chain grades accurately. Learn how to identify grades and marking of transport chains. Web chain grades are a standard method for showing the ultimate breaking strength (tensile strength) of a chain. Web the biggest difference between grades of chain is that carbon steel chain—grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—grade 80, 100, and 120—is recommended for use in sling assemblies and overhead lifting applications. Web this guide will delve into the various chain grades used in the rigging industry, their common applications, differences, potential problems, and common misuse scenarios. Web which chain grade should be used for which type of application? This article embarks on a journey through the ratings of chain grades, deciphering the significance behind the numbers and letters that define strength, durability, and performance. Astm states that alloy chain shall be able to elongate a minimum of 20% before fracture (7.3.5). Web chains come in various grades, each denoting specific characteristics and applications. Web complete flatbedder’s guide on cargo chain grades, grade types and chain strength with chart. Common grades include grade 30, grade 43, grade 70, grade 80, and grade 100, each tailored for distinct use cases.What Are the Different Grades of Chain?

Helpful Links Catena Inspection & Engineering Services

Chain Grade Rating Chart Ponasa

Chain Grade Chart A Visual Reference of Charts Chart Master

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Chain Grades And Strengths Chart

Chain Grades Chart Cargo Chain Strength And Grades Guide, 50 OFF

What Are the Different Grades of Chain?

Comparing Chain Grades U.S. Cargo Control US Cargo Control

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Web The Different Chain Grades Explained, With Their Permitted Uses And Free Charts/Cheats To Download And Print.

Alloy Chain Grade 80 Or Grade 100 Should Be Used For Overhead Lifting.

Grades Wise Chain Usage And Safety Standards.

Web There Are Five Grades Of Chain:

Related Post: